Transforming Global R&D Operations through AI/ML Automation and Experience Strategy

Led the end-to-end CX and Product Design Strategy for Johnson & Johnson’s R&D Global Material & Trade Shipping Solution, reimagining compliance and operational workflows across regions.

Designed a scalable AI/ML-powered platform and new operating model that reduced operational risk by 50%, accelerated shipment review time, and achieved 75% adoption across global teams.

Experience Strategic Lead

A Strategic End-to-End Journey Centric Design Framework

A Strategic End-to-End Consumer Experience (CX) Journey Centric Design Framework that leverages AI/ML and aligns UX strategy and design to standardize regulated global operations, optimizing R&D, commercial, and compliance workflows, drive operational efficiency and deliver measurable impact across pharmaceutical ecosystems to advance patient health outcomes.

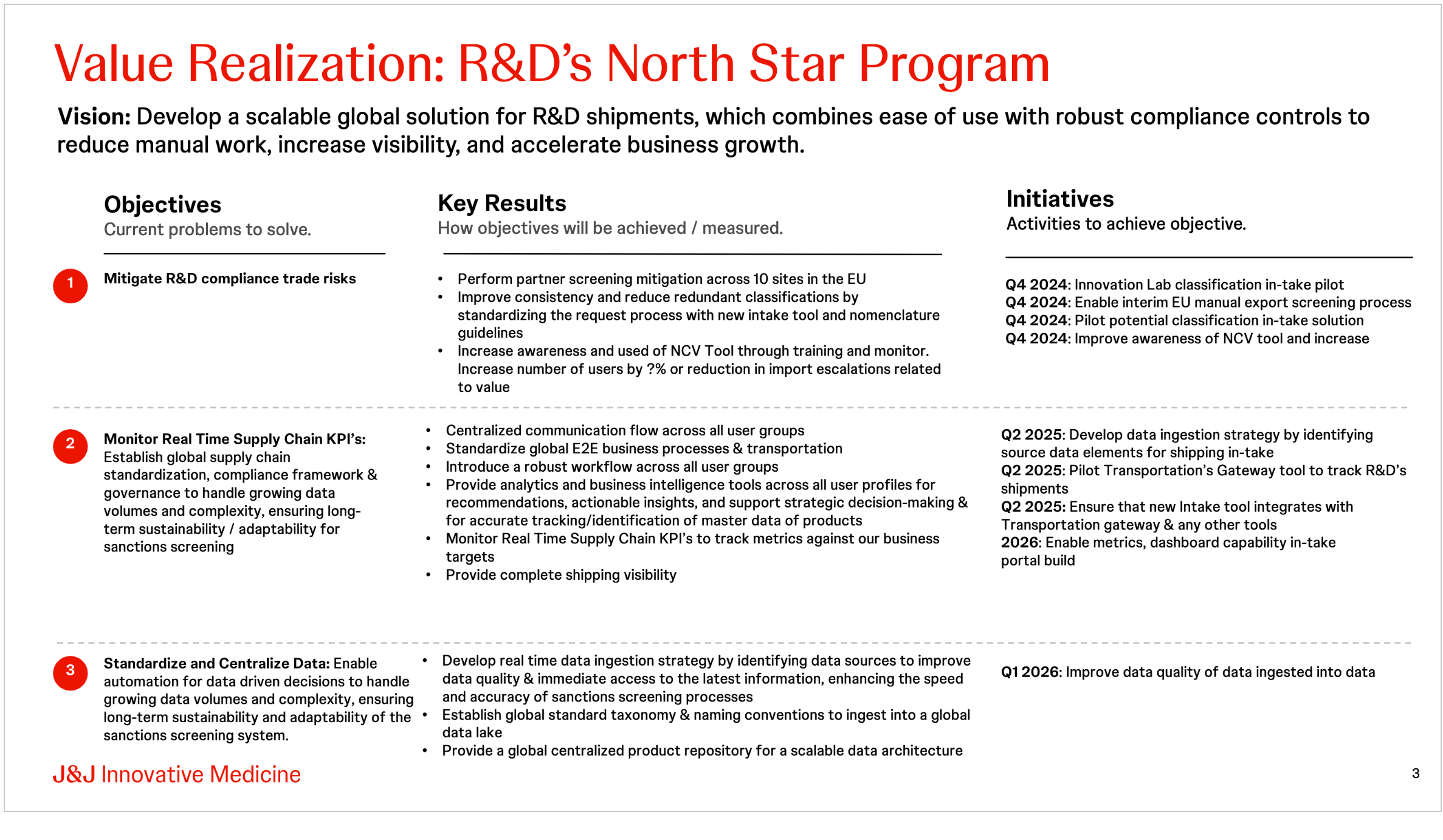

Define the North Star

Experience

Establish a unifying standardized global vision that aligns business goals with consumer/customer needs and experience to accelerate the discovery and development of new treatments.

Ecosystem, Workflow Mapping & Systems Thinking Design

Standardized material classification, trade compliance review operations and global process and system harmonization.

Governance & Regulatory Compliance-Driven Experience

Streamline export/import process to mitigate compliance risks and increase visibility into shipments and record keeping.

Align customer insights & business goals

Map user’s workflows, determine OKR’s & UX-KPIs for operational efficiency based on business goals.

Overview

In 2022, policymakers imposed unprecedented sweeping trade controls, including increased numbers of global individuals and entities to sanctions lists.

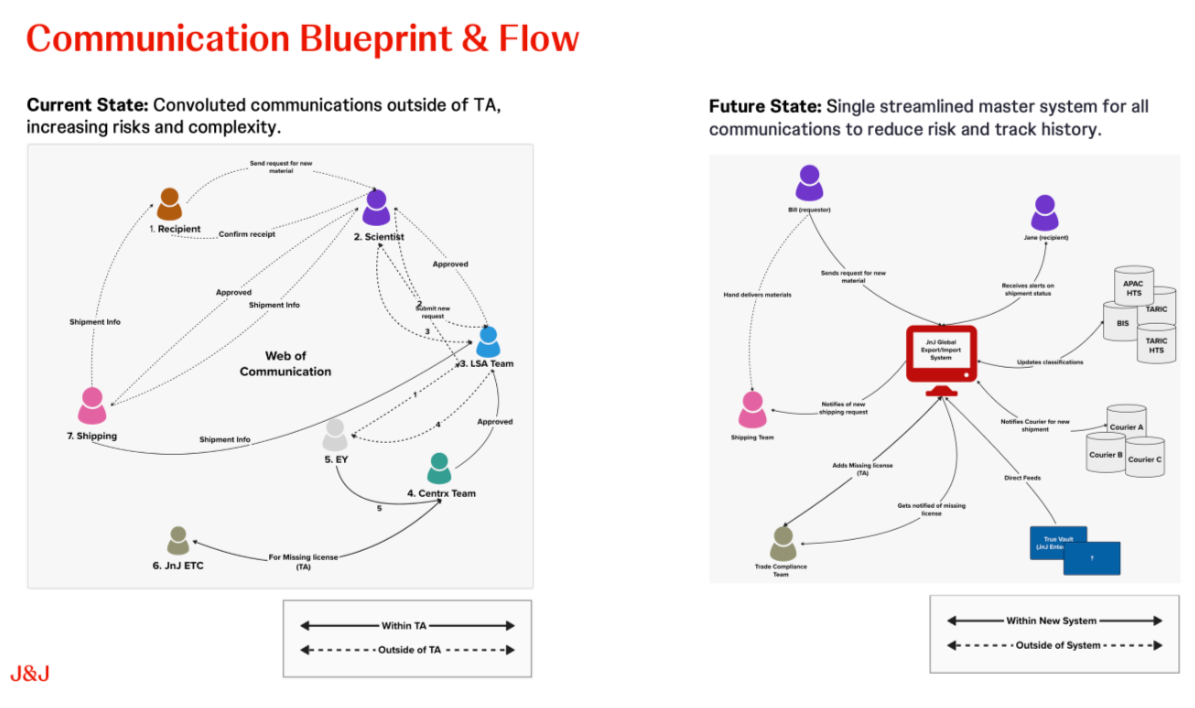

In 2023, a remediation process for US R&D exports was implemented, but it remained reliant on manual steps and redundant processes. The lack of visibility and oversight of R&D shipments posed a significant export control and compliance risk, while the interim solution was not scalable for global implementation across other regions.

The Challenge

Lack of an enterprise system for managing recipients data, resulted in record duplication of 55,000 consignees in the EU when in actuality there are 1,705 unique records.

Manual efforts created a high-friction user experience, with material classification requests taking up to 6 months to complete impacting overall R&D’s business goals.

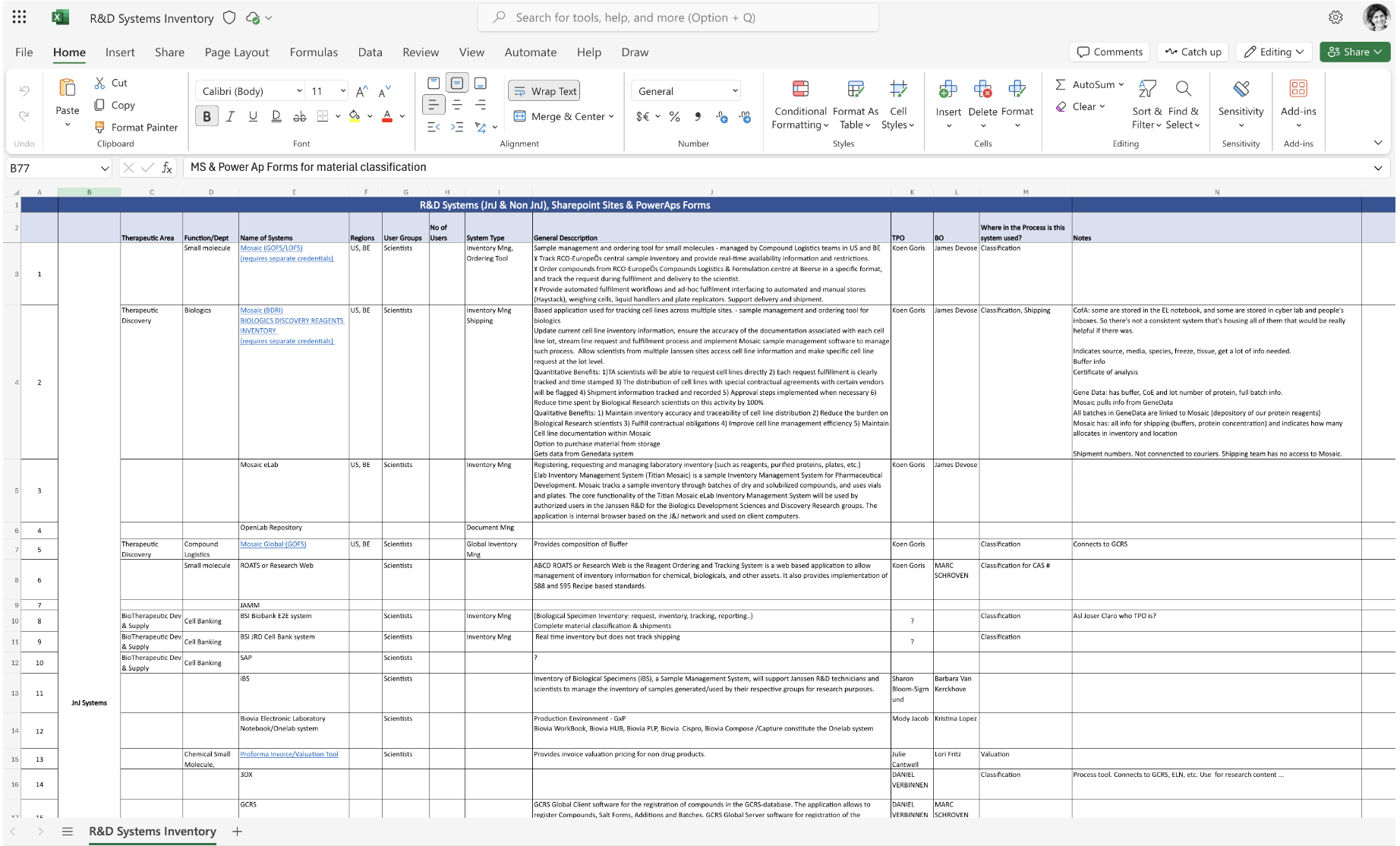

R&D’s global material classification and shipment process was managed through fragmented, site-specific legacy solutions, where multiple teams use different systems and manual processes without consistent trade compliance checks or record-keeping. Lack of integration and oversight created a significant export control risk for J&J, with limited visibility into the status of classification and shipments.

Identified current customers’ journeys, pain points, wish list to design and ensure seamless and intuitive experiences across all digital and physical touch points while incorporating a standardized global business framework.

Business Operations

Additional required support staff for manual reviews and R&D lead times with inconsistent material classification and valuation with limited audits, reviews, and validations to determine aspects of compliance.

Enterprise Workflow

Lack of compliance review process and workflow with no denied party screening, created compliance gaps across the EU sites and exposes J&J to risk.

Central Database

Lack of central database for J&J shipping recipients and materials used for research.

Manual Data Entry

Standardized templates used in the US are lengthy, requiring requestors to consult multiple systems and manually input data.

Fragmented tools/processes

Lack of integration across R&D Inventory Systems which support SDS documentation and DG determinations.

System Integration

Shipment requests are not integrated with compliance review processes and are manually entered into the existing Global Trade Management system by additional support teams.

Opportunity

User Research Strategy & Insights

Conducted qualitative and quantitative research to understand customers and business needs, behaviors, and pain points, translating insights into actionable design solutions.

Stakeholder Collaboration

Partnered with R&D global business partners, technology, and product teams to ensure solution meets R&D’s business and customer-needs.

Captured current eco-systems and all access points for each user profile with pain points and

wish list.

Mapped use cases into topics to uncover users' mental model, identify BE’s unique business and

user needs.

Identified R&D’s critical KPI’s and business goals to support business case.

Drafted and prioritized user stories based on business and user needs to identify an MVP and product roadmap.

Journey map captures full business workflow, across all digital and physical touch points, with happy vs sad path metrics across all user groups.

Documented internal and external systems/tools utilized to classify and ship material.

The opportunity lied in evaluating R&D’s current material classification and export shipment process by conducting a deep analysis based on data, analytics, and user research across R&D’s complex eco-systems.

By connecting the dots and telling user’s story, it allowed to identify the UX strategy for innovation and establish R&D’s overall global operations into a scalable and sustainable solution across all regions.

Operational Framework

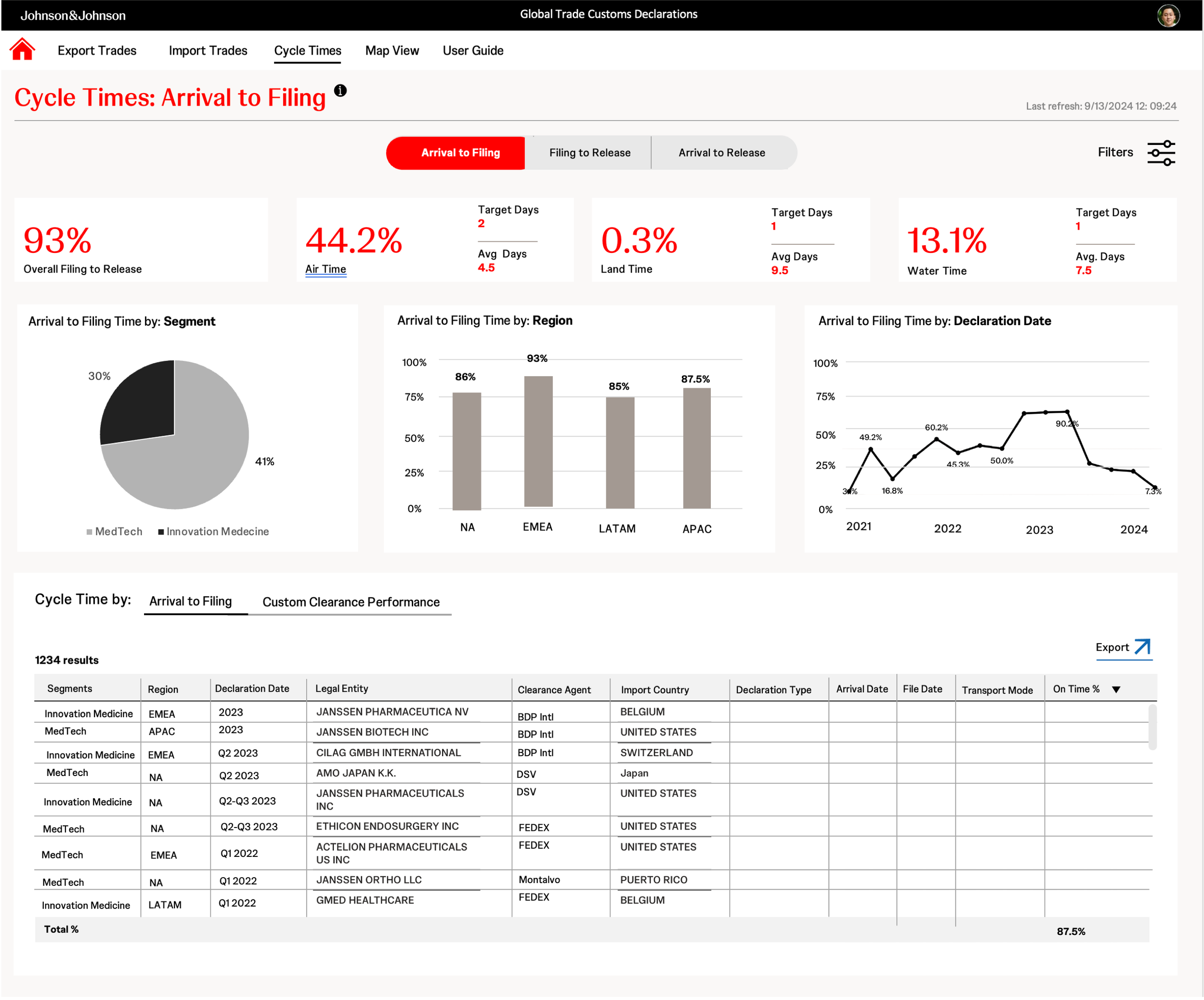

A new strategic business framework to standardize and improve R&D’s operations, minimize compliance risks, and provide greater visibility over the global supply chain across all regions.

AI/ML Integration

Introduced greater automation for material classification, valuation and license determination; flag compliance risks to reduce manual checks.

Centralized Platform Design

A centralized platform that can handle material classification and export shipment processes, with region-specific data.

Cross-Region Collaboration

Develop features that foster collaboration across all regions on complex classifications or shipments.

Scalable Architecture

Ensure the platform architecture supports scalability for global expansion.

Data-Driven Insights

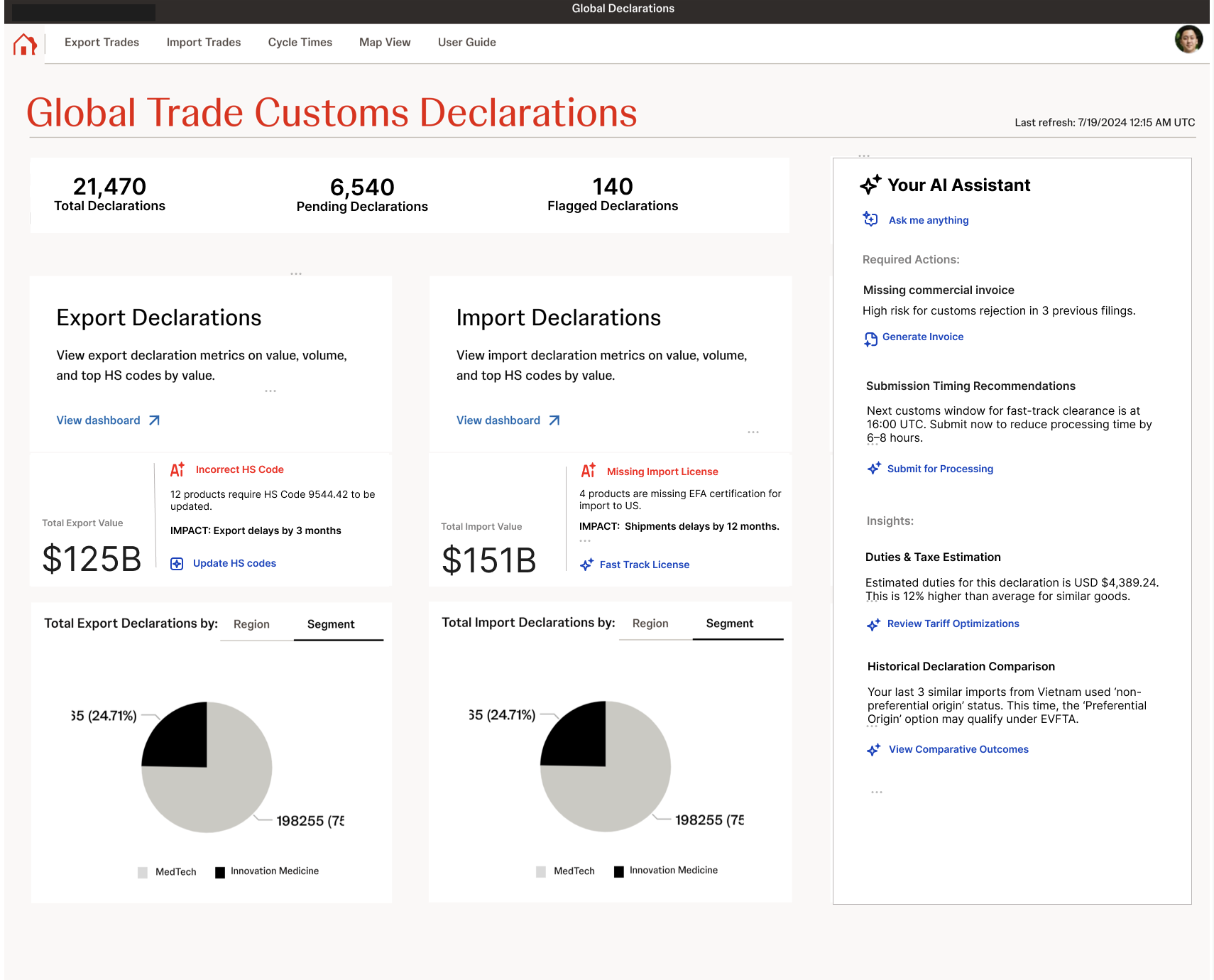

Provide real-time analytics with data visualization with AI/ML capabilities for actionable insights.

Personalization & Localization

Region-specific variations for compliance, languages, etc, allowing users to operate in their local contexts while ensuring global standards are met.

Compliance & Risk

With AI/ML capabilities, provide regulatory compliance through real-time updates, audit trails, and predictive risk management features.

Design Thinking Workshop

Location: Brussels, Belgium

Partners: Deloitte & Stanwick (Belgium)

Participants: Over 35 business partners across R&D, Supply

Chain, and Trade Controls from US and Belgium.

The workshop aimed to share early findings from user research, highlighting R&D’s challenges in global material classification and shipment processes. The goal was to secure buy-in from all business units and align on a roadmap to address critical business needs.

Through visual maps, the complexity of R&D outbound shipment processes for BE and the US was brought to life. A printed, on-the-floor process visualization was paired with an interactive Mural and Miro board displayed on-screen. These tools enabled participants to explore the intricate end-to-end process, delve into detailed insights, and better understand the user experience.

Business Consensus

Align all business partners on the key issues, such as manual processes, fragmented systems, lack of visibility, compliance risks; plan and agree on a road map for short term vs long term goals and business needs.

CX Strategy

Provide XD strategy and recommendations for improving processes, with a focus on creating a sustainable global standardized business framework for future growth.

Establish UX KPI’s Metrics

Define key performance indicators (KPIs) to measure process effectiveness and track progress over time.

Optimize Operations

Design a sustainable and consistent operations across all regions to improve overall supply chain building a stronger logistics process within the R&D landscape.

The worksop provided business partners an interactive view of R&D’s end-to-end process, with detailed steps and insights, for a deeper understanding of users journey, pain points and overall story.

Business partners identified and agreed most critical business needs.

Planned and prioritized a high level multi year product roadmap based on business needs.

Various artifacts were created to communicate the XD strategy and business impact to stakeholders and sponsors, ensuring alignment and securing early buy-in for the proposed solution.

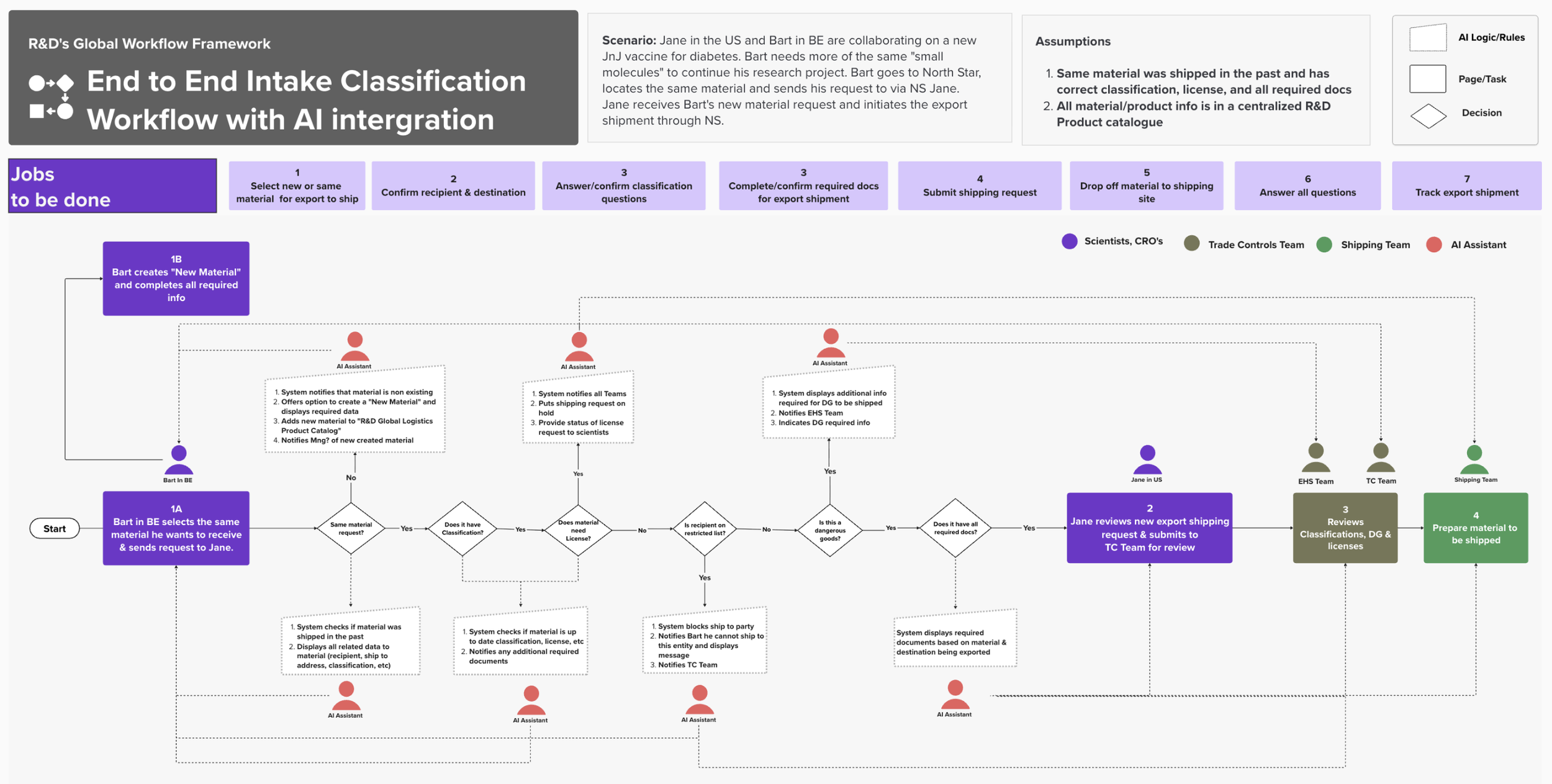

R&D’s Logistic & AI Assistant Classification Solution

Mapped end to end workflow for R&D’s AI Assistant integration to identify required AI logic across all user groups.

Created a MVP prototype to validate initial material classification solution and ensure scalability across all regions.

Trade Control AI Assistant Risk Management Solution

Personalization & localization for region-specific compliance rules to enhances adoption and maximizes the utility of AI technology.

Challenge

The absence of a dedicated trade controls system made it difficult for J&J to manage material imports/exports and track restricted parties, creating compliance risks with international regulations.

Strengthened compliance with international trade regulations and improved data transparency and record-keeping procedures.

Reduced operational risk while ensuring accuracy and efficiency across global R&D shipments.

Opportunity

Design of a Global Trade Controls solution with AI/ML risk forecasting and live data visualization. Introduced streamlined processes to improve compliance, visibility, control, and accuracy in the R&D shipment process, resulting in a 90% adoption rate.

Provides monitoring and oversight of business activities and data feeds to ensure adherence to regulations.

Identifies restricted trade with specific countries or entities, often based on foreign policy or national security considerations.

Enterprise scale within the complex of J&J’s environments for better system integration, synchronized data sources, governance, and sustainability, etc.

Solution

Experience Strategy

Defined the overall global end to end UX strategy to align with R&D’s business goals and customer expectations.

Business Operating Model Optimization

Identified inefficiencies and opportunities for process and workflow improvements to enhance operational effectiveness and service delivery.

Conducted user research activities and leveraged data-driven insights to identify short and long-term strategies, inform overall design strategy, MVP and product roadmap across all regions.

The proposed XD strategy leverages AI/ML technologies to optimize business operations, automate processes, improves global regulatory compliance, mitigates risks, avoids trade bans, reputation damage, creating a robust, scalable, and compliant framework for R&D’s global operations.

Centralized end to end solution with AI Assistant to optimize R&D’s full supply chain shipments with greater automation based on international standards.

Data Analysis with predictive insights for more accurate material classification and shipping optimization.

Global Standardize Compliance procedures across all regions to minimize export control risks and ensure legal adherence.